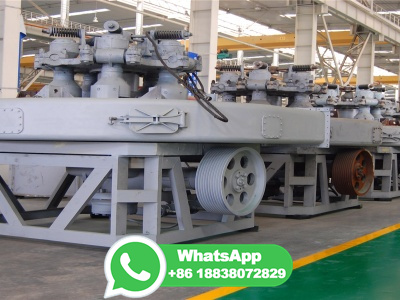

Size Reduction Milling Hosokawa Micron Powder Systems

From lab/pilot to production requirements, Hosokawa Micron Powder Systems offers a complete line of size reduction technologies. Whether you call it size reduction, micronization, milling, pulverizing, jet milling, air milling, or simply grinding, we can help. Our broad application expertise allows us to help you select the technology that ...