PDF 1 ASEAN GRINDING PROJECT KHD Humboldt Wedag

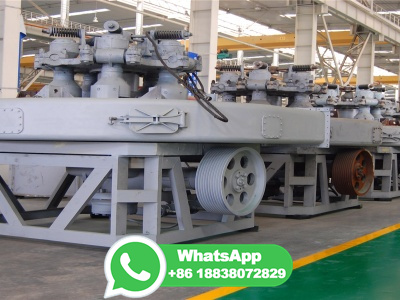

mill circuits. KHD's comflex grinding units are always engineered around a roller press as core grinding mill in close circuit with static and dynamic separators. Figure 1 and the equipment overview in Table 1 outline the new raw material grinding circuit in finish mode and the equipment chosen by SCCC and KHD. The grinding unit for SCCC uses two